Manufacturing Software

Manufacturing Software

-

Ostendo Queensland Office

1 year, 6 months ago

Ostendo Support Queensland

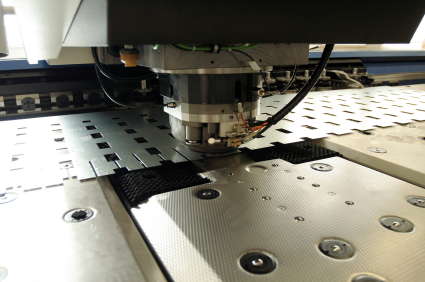

Ostendo provides manufacturing functionality which will suit:

- Manufacturers of Custom and Repeat Products

- Engineering Fabrication and Jobbing

- Food and Chemical Process Industries

- Custom and Repeat Product Manufacturing

- Custom Bill of Material generation based on customer specific requirements.

- Multi-level bills of material.

- Serial No. , Batch No. , Revision No. and Expiry date inventory management and traceability.

- Simple question and answer interface to design, cost, and price customer-specific products and services.

- Based on answers to the questions at the quote or sales order entry stage, the system automatically generates and stores a unique design to make the product or service at a later time specifically for that customer e.g. BOM and routing.

- Custom products or services with a future ongoing service commitment can be converted to a customer service asset at time of sale.

- Purchasing in local or overseas currencies.

- Landed costing with the option of allocating freight and customs charges across the products in a shipment by price, quantity, volume, weight or duty percentage.

| NZ: +64 9 446 1204 AU: 1800 764 058 Email: support@solutionm.co.nz |

Engineering Fabrication and Jobbing

- Estimate and quote preparation directly from last cost and supplier catalogue data stored in Ostendo.

- Labour, material and subcontractor mark ups can be grouped and easily manipulated.

- Clear job list with status tracking, to line level, user defined tracking codes and colours.

- Job Calendar with drag and drop functionality for scheduling labour and/or machinery resources for each task.

- Timesheet entry and labour tracking with actual job costs to date.

- Real time work in progress, and time and cost completion percentage at all levels.

- Job estimating/quoting

- Detailed budgeted planned, actual and projected costs at the various task, job, and project heirachy levels

- Progress claims and retention tracking by job, consolidated invoicing by project.

- Purchase orders and supplier invoices can be allocated directly to the job to maintain actual job costs to date.

- Supplier invoices and catalogues can be imported directly into Ostendo

- Import of design data from AutoCAD and Solidworks output files.

- Shop Floor labour time and material usage quantities can be entered from a terminal in the workshop

| NZ: +64 9 446 1204 AU: 1800 764 058 Email: support@solutionm.co.nz |

Food & Chemical Process Industries

- Multi-level bills of material for recipe management.

- Batch No. and Expiry date inventory management and traceability.

- Co-product and bi-product management.

- Recipes with scrap %, set up and run time labour by operation

- Multiple stocking units of measure, barcoding and unlimited user-definable properties for inventory items.

- Comprehensive pricing levels, quantity breaks, discounts, and add-on sales against inventory items.

- Scheduled maintenance for factory assets with service history and operating hours.

- Purchasing in local or overseas currencies.

- Landed costing with the option of allocating freight and customs charges across the products in a shipment by price, quantity, volume, weight or duty percentage.

- Direct labour, variable overhead and fixed overhead management

- Shop Floor labour time and material usage quantities can be entered from a terminal on the production shop floor.

| support@solutionm.co.nz |

| AUCKLAND | MELBOURNE |

|

9 Huron Street |

Level 9, 440 Collins Street |

|

Ph: +64 9 446 1204 |

Ph: 1800 764 058 |